With the rapid development of China's aluminum foil Mylar industry and the changes in the market, the production capacity of slitting equipment has been continuously enhanced, and the product quality needs to be further improved. According to the current use situation, the performance requirements of various manufacturers for slitting machine during use are summarized, which need to be improved in the following aspects:

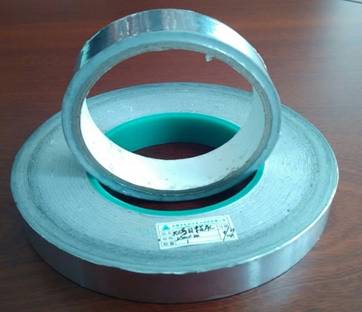

Improve the production capacity of the slitter. Generally, the unwinding diameter of aluminum foil is about 1000mm, and the winding diameter can reach 600mm;

Improve the convenience of operation. The diameter of the original aluminum foil coil increases, and the labor intensity is high for the operator. Therefore, the equipment must be required to reduce the labor intensity. The unwinding system is divided into axial unwinding and non axial unwinding. Generally speaking, no axial unwinding is convenient for winding up and clamping. As long as a lifting car is used, the winding up and unloading can be used to reduce the labor intensity.

Aluminum foil Mylar improves cutting speed. It is increased to 200-300 / min on the basis of the current slitting speed. Increasing the cutting speed of aluminum foil is the main way to improve the production capacity. High speed is one of the main means to increase the output and reduce the cost of enterprises;

The control operation of aluminum foil Mylar must also be simple and intuitive, such as setting tension, tension curve, unwinding diameter, slitting material and thickness, winding width, length and other parameters, which can be achieved through simple operation, ensuring the quality of aluminum foil winding with equipment accuracy and eliminating the influence of human factors;

Aluminum foil Mylar equipment is safe and reliable. When the equipment operates at high speed, the safety of the operator and the safety of the action sequence of the equipment shall be guaranteed. The deviation corrector is sensitive to ensure that the edge of the aluminum foil roll is neat and free of staggered layers. The meter setting is stable to ensure that the aluminum foil winding length deviation is within a certain tolerance range.